Case Studies

Fireray detectors meet the challenge of protecting the Ocean Grove Auditorium

Reflective beam detectors from FFE have provided a critical component of the fire detection strategy needed to protect an irreplaceable architectural treasure.

Key Facts

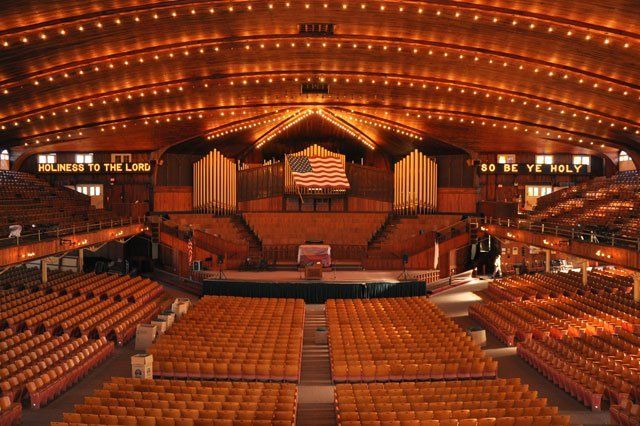

- The Great Auditorium in Ocean Grove, NJ, is an impressive structural steel and wooden building covering a footprint of 36,225 square feet, with a center roof line height of 84 feet and a central octagonal tower reaching 119 feet above the town below. The total combustible fire load of the structure equates to that of a massive lumberyard.

- Rapid early-stage fire detection is essential to give time for the sprinkler system to be activated and contain the fire to its area of origin. However, the building is not heated or air-conditioned which severely limits the options for providing early fire detection.

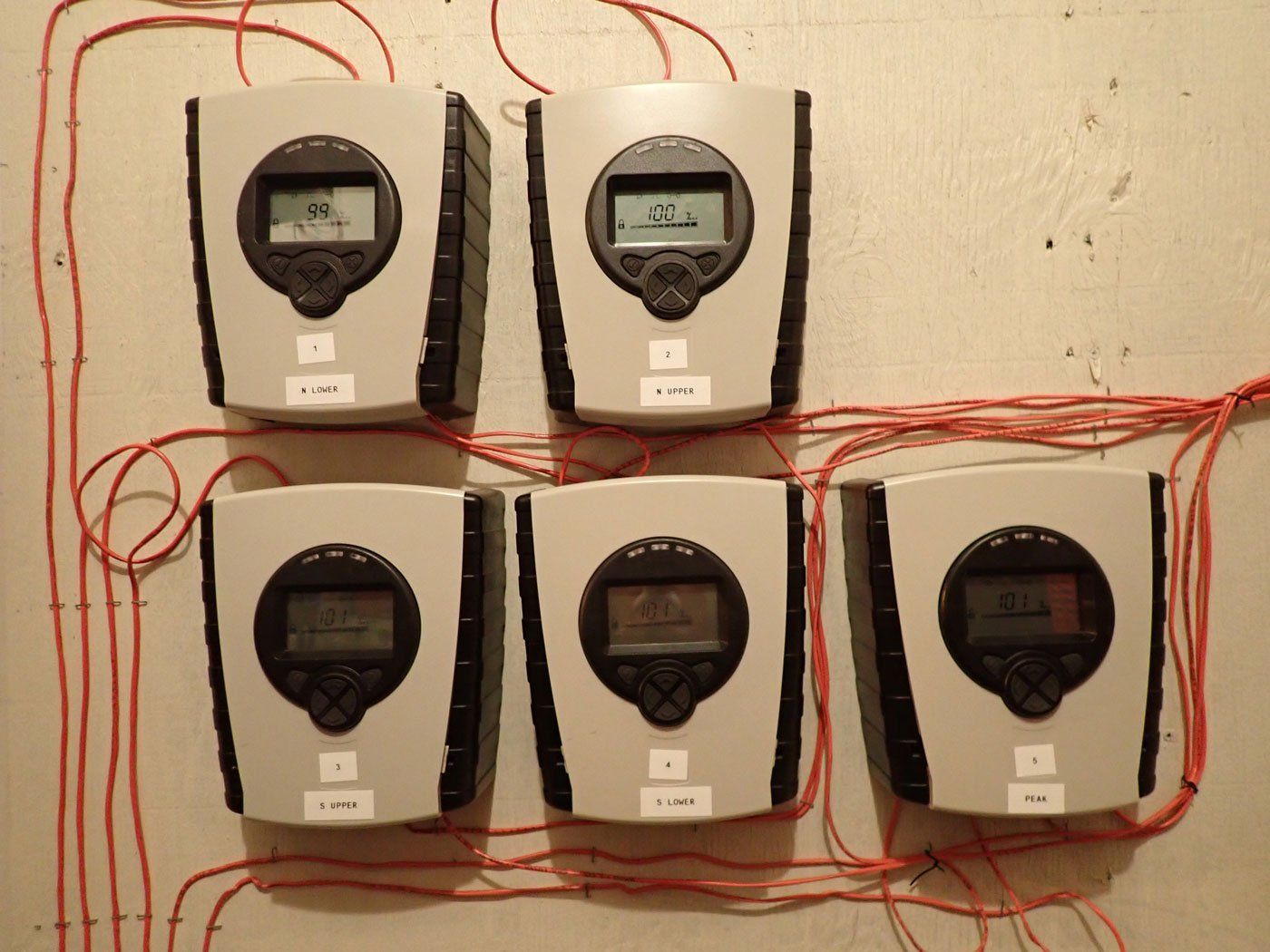

- As part of the continuing work to provide complete fire detection coverage throughout the auditorium, five Fireray® 5000 reflective beam detectors have been successfully installed and tested in the main attic space, which contains a maze of structural steel needed to support the wooden auditorium ceiling and roof.

- The estimated cost saving in installation alone compared to other smoke and heat detection options was over $100,000, with ongoing reductions in inspection, testing, and maintenance costs.

- The successful installation of the Fireray 5000 detectors in the main attic space is a critical step in providing the early fire detection necessary for the sprinkler protection of this historic building.

A unique treasure hiding in plain sight.

Although wood has many excellent qualities as a construction material, resistance to combustion is not one of them, and so any building which uses wood extensively in its structure needs particular attention paid to its fire protection systems. When the building in question can accommodate over 6000 people and is surrounded by other historic wooden buildings in the center of one of the most well-preserved Victorian towns in the United States, this need becomes even greater.

This was the situation facing Carl Willms CFPS SET of Fire Safety Consultants Inc. ten years ago, when he was first asked to review the protection systems at the Great Auditorium in Ocean Grove, New Jersey. This magnificent building was constructed in 1894 by the Ocean Grove Camp Meeting Association, affiliated with the United Methodist Church. It was completed in ninety days by an army of local shipbuilders, whose influence can clearly be seen in the extraordinary ceiling of the main auditorium, which resembles the ribbed hull of a sailing ship. The imposing historic building has a rectangular structure made of a steel frame clad in wood, with a footprint of 36,225 square feet. It is used throughout the summer for services, special events, and concerts, and houses one of the twenty largest pipe organs in the country, containing no less than 10,823 pipes varying in height from a few inches up to 32 feet.

Reviewing the situation

Carl is a highly experienced fire investigator and system designer: a Certified Fire Protection Specialist, a NICET-certified Level IV Senior Engineering Technician, a principal member of the NFPA-72 National Fire Alarm and Signal Code Protected Premises technical committee, a member of the NJ State Fire Protection Subcode Committee and a Professional Member of the SFPS (Society of Fire Protection Engineers). He was brought in by the building’s facilities manager to review the suitability of the existing fire detection and protection systems.

A risk analysis indicated that the most likely fire ignition scenario would be electrical in nature; other less likely but possible scenarios included lightning, vandalism, or maintenance operations. The overall fire protection strategy was clear: the significant fire load of the wooden structure (equal to that of a massive lumberyard) requires that a fire be detected in its early stage to activate the pre-action system. This delivers water to the sprinklers in the area of the fire’s origin before the fire can grow to a size which the sprinkler system would be unable to contain to this area.

The review indicated that the existing fire detection system, comprising rate-of-rise and rate-compensated heat detectors, was far from being able to reliably detect a fire in time to meet this objective. The existing layout of spot-type heat detectors scattered throughout the building was grossly inadequate. As an example, the wooden ceiling of the auditorium has a maximum height of 34 feet above the floor but contained only 12 heat detectors.

Carl set to work to design a fire detection system to protect this irreplaceable building within the limited financial resources available to the owners. The technical obstacles were exacerbated by the fact that the building is not heated or air-conditioned, which severely limits the options for providing early fire detection due to the restrictions in permitted operating temperatures of many technologies. “In all my years in the fire detection and protection industry, this has been the most challenging project I’ve ever encountered,” he says.

Tough at the top.

The first step in the project involved installing a new addressable fire alarm control panel that could accommodate the potential system expansion and upgrades. Along with the new panel, heating was provided in the fire alarm panel room. The next major improvement was the installing of an aspirating smoke detection (ASD) system across the beautifully curved ceiling which, owing to its size and curved profile, is not well-suited to either point or beam detectors. The pipework for this system was fitted to the floor of the attic space above the wooden ceiling, with 81 sampling ports that penetrated the ceiling at intervals of 17-20 feet. The ASD controllers were installed in a small booth in the attic that was fitted with heating and air conditioning to maintain operating temperatures within the UL-listed temperature limits of the equipment. This booth was also provided with high and low temperature alarms and would become the optimum installation location for other electronic hardware supporting an expanded fire detection system.

However, the attic space itself was another major concern, as the scattering of rate-compensated heat detectors present was inadequate. It is also a highly cluttered space, with spars and braces forming a tangled network of obstacles, requiring a considerable number of spot-type heat detectors to give sufficient protection – far too difficult and expensive to install.

Linear heat detection (LHD) was the initial design concept for protecting this space, which included strapping the detection cable to the existing sprinkler system branch pipelines from the base of the attic to its peak. After numerous visits with potential contractors, the access to this piping was clearly a major obstacle. The costs involved to install the linear heat detection were estimated to exceed $100,000 for the attic alone. Air-aspirating detection was another possibility but access to install the piping was still a significant problem. There was no way to safely install ASD or LHD in the attic space with only a single layer of 1” wood between the attic flooring and a 34-foot drop to the auditorium floor!

Instead, Carl decided to try and install reflective beam smoke detectors in this space, partly to protect the attic itself, and partly as an additional layer of detection of a fire originating in other areas of the auditorium where smoke might travel into the attic space. In several locations, there are wooden ventilation grills in the auditorium ceiling which communicate with the air in the auditorium below. There are also numerous open organ pipe chases that terminate in the attic, so it might be possible for smoke from a fire to migrate through these into areas of the attic space.

Although beam smoke detectors offered the most promising solution, it was far from certain that they would work. The cluttered space made beam blockage a distinct possibility – would it be possible to find a path with enough clearance for a beam to pass across the attic and be reflected back again? In addition, maintaining alignment across the attic space was anticipated to be critical considering the likelihood of building movement due to high winds; the auditorium is over 80 feet high at the apex of the ceiling and has an uninterrupted view of the Atlantic shoreline less than a quarter of a mile away.

Tried and tested.

Carl had enjoyed many years of positive experience using FFE’s Fireray® 5000 beam detectors in other applications. With so much at stake in this project, he wasn’t taking any chances, so he worked with building maintenance staff and they installed one of these detectors in the attic for a feasibility test. The transmitter-receiver unit was mounted on the east wall of the attic; fortunately, this area was accessible using scaffolding left over from roof repairs following superstorm Sandy in 2012. The controller was located in the heated and air-conditioned attic booth. The reflector was located on the west wall accessible from an extension ladder, at a location identified using the integrated laser in the detector. Then, through trial and error, a path was found that had just enough clearance around the beam to allow it to be aligned successfully. The alignment itself was the easiest part due to the detector’s motorized mirrors and automatic alignment routine.

After three weeks, the detector beam was maintaining its alignment admirably, with a signal strength above 95%. Encouraged, Carl and the building maintenance staff went ahead and installed a further four beam detectors, each with its own controller so that the status of each beam could be monitored continuously and eventually connected to the main fire panel.

As well as alignment, Carl’s other concern was sensitivity. There was no doubt that the beams would detect a fire in the attic, but what about smoke rising from other areas? One of the advantages of beam detectors is their very long optical pathlength, which means that even a low concentration of smoke can be detected because it penetrates a prolonged length of the beam and gives appreciable scattering of the infrared light. However, that situation normally applies to open spaces under ceilings. In this case, Carl speculated that smoke coming from the main auditorium might only penetrate the attic space at a few specific points where wooden ventilation grills are located, so some of the benefits of the long pathlength could be lost.

With this in mind, Carl decided to use the highest sensitivity that the detectors would allow, even though this contravened the rules regarding UL listing of the system and increased the risk of a false alarm. He reasoned that unusual circumstances called for unusual measures, but in his engineering judgment, it was an acceptable approach.

In the first few months of the system being installed, Carl’s decision has been vindicated and his faith in the FFE detectors rewarded with trouble-free operation. The motorized mirrors have maintained alignment of the beams at all times, and any contamination of the lenses in the dusty attic environment has also been handled well by the detector’s compensation software so that reduced signal strength has not been an issue.

Money saved and objectives met

The ability to protect the attic space with the Fireray 5000 reflective beam detectors gave a tremendous cost saving over any other potential fire detection method. With the assistance of maintenance staff, the process of installing the detectors on the east wall, running a single cable from the unit to the attic booth, and mounting the reflectors on the opposite wall was easy and efficient. The cost savings were estimated to be over $100,000 versus other smoke and heat detection options.

The long-term inspection, testing, and maintenance costs are also significantly reduced. There is no need to test individual spot heat detectors or linear heat detection runs, or access ASD piping for cleaning and maintenance. A simple UL-approved sensitivity and alarm test is all that is required, which is performed safely from the controllers in the attic booth.

Following the successful installation of the detectors, Carl can reflect on his choice of detection system. “Fire protection systems engineers struggle with designing cost-effective early fire detection systems in unheated locations. In many cases, heat detection cannot provide sufficient warning of a fire in its incipient stage to address the risk. Furthermore, some unheated building applications need smoke detection capabilities to meet the objectives of protecting life and property. Although aspirating smoke detection systems do provide the capability of very early detection, they are very costly to install and maintain. Where heat detectors simply do not meet the design intent and a horizontal unobstructed visual path with a radius of 3 feet exists, I use the Fireray 5000 as the optimal solution for my projects.”

Every journey begins with a single step…

Although already in progress for ten years, in many ways this project is still in its infancy. Carl has other plans concerning the protection of the Great Auditorium. Where spot heat detectors are currently the only means of fire detection in many areas, he plans to install at least 15 additional beam detectors. In areas that do not have the necessary line of sight across the area to be protected, additional ASD systems are planned. In various areas with limited combustible contents such as the dirt floor basement area, linear heat detection tied to the sprinkler pipe is ready to be installed. Next year sees a planned structural reinforcement of the pipe organ supports which may present an opportunity to access areas above the pipes and improve the protection of this valuable asset. For the moment though, he is pleased with the significant step forward in protecting the attic space of this landmark building using the trusted beams of FFE’s Fireray 5000 detectors.

Do you have an interesting project with Fireray or Talentum detection? Contact us at marketing@ffeus.com and we can help write and publicize it.

EXPERT INVESTIGATORS

We are experienced in applying the NFPA-921 scientific methodology to our fire and explosion investigations and other fire protection loss projects where systems fail to operate or operated inadvertently.

RESPECTED

While investigating and delivering the opinions and conclusions regarding a loss, we strive to prevent confirmational biases when determining the validity of factors that contributed to the loss.

TRUSTED

Fire Safety Consultants works within the guidelines of NFPA-921 to gather and analyze the facts and data to develop hypothesizes that are thoroughly tested to determine if an expert opinion will withhold intense scrutiny.

Need Help?

Frequently Asked Questions

Contact Us

Have a question? We are here to help. Send us a message and we’ll be in touch.